Seamless pipe

ADVANTAGES OF USING SEAMLESS PIPE

Seamless pipe is also used under the name of pipe not welded. The manufacturing process of the seamless pipes begins with a steel ingot. This ingot is then heated to high temperatures, stretched and drawn on a mold, until it takes the shape of an empty tube.

The best advantage of the seamless steel pipes is the increased ability thereof to withstand pressure. The weakest point in a welded steel pipe is the welding point. As a seamless pipe has not been welded, it does not have this welding point, being just as strong on the entire circular line of the pipe.

Also, it is much easier to determine pressure calculations without the need to consider welding quality. Although seamless pipe may sometimes be more expensive than welded pipe, this increased ability to withstand pressure allows you to use tubes (pipes) that are thinner and lighter, which may help in costs decrease.

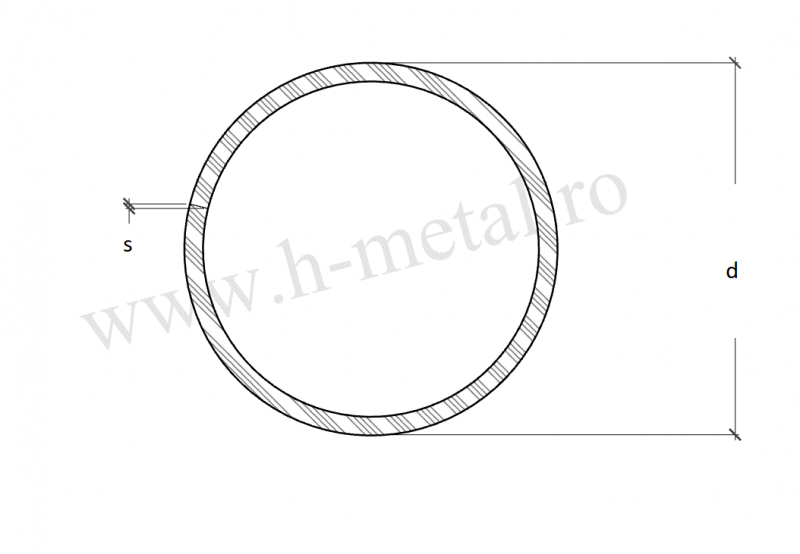

As it is not welded, the seamless pipe has a perfectly round cross section.

Seamless steel pipe may sometimes be more expensive than other forms of steel pipe, but it is also much more reliable. Usually, the pipes fail at the welding point, but as the seamless pipe does not have such a point, it is not subject to this defect.

These benefits make the seamless pipe the preferred material in a wide range of applications, including ship building, pipelines, oil rigs, oil platforms, equipment of oil field, pressure recipients, machine parts and naval platforms.

At the same time, seamless pipe is also used in the field of metal constructions as structural element, where superior mechanical resistance is needed. An additional advantage of the seamless pipes is that they work well in harsh conditions, which means that they may be used in very cold or hot environments.

Technical data for the seamless pipes

Manufacturing standards: EN 10208, EN 10210, API 5L, API 5B

Steel grade: S355J2H, St52.0, Grade A, Grade B

Length of production: between 4 and 12 ml

Quality certificate: 2.2 or 3.1B type, according to EN 10204