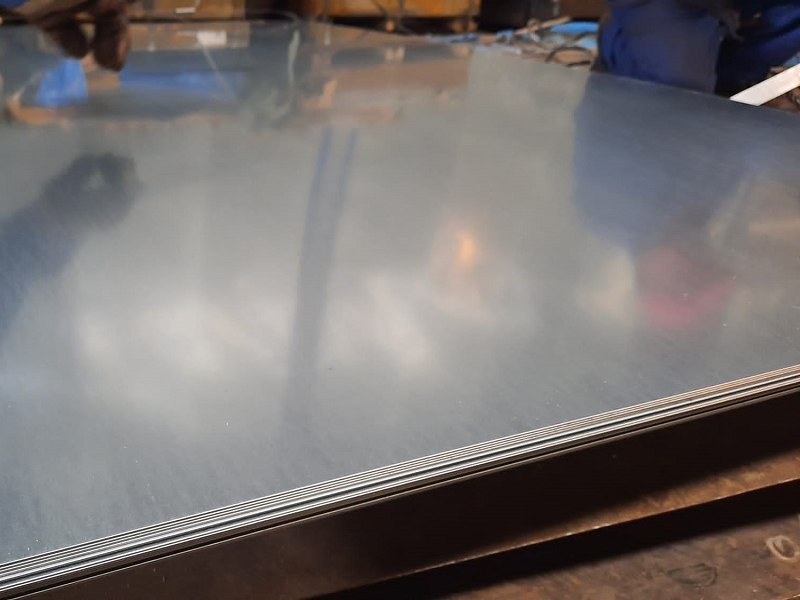

Galvanized steel sheet

Galvanized sheet is a steel sheet that has been galvanized to prevent corrosion. The sheet is covered with a zinc layer on both sides, the coating is expressed in grams of zinc applied per square meter of product.

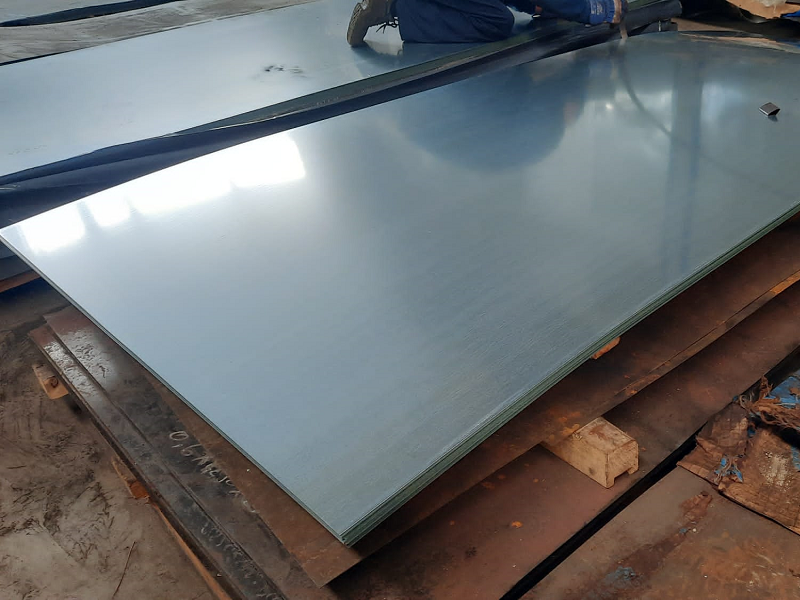

The thicker the zinc layer applied, the greater the corrosion resistance. In the case of the same amount of zinc coating, the medium is the most important corrosion factor. The strength of the zinc layer is lower in industrialized areas than in rural areas where air is less polluted. In addition, the operating life of the galvanized sheet is 5-10 times longer when used indoor than outdoor environment.

Galvanized sheet Z275 provides long-lasting strength for products made out of this material. This zinc degree is very resistant to the action of water, snow, ice, dust, sun, etc. It may be used successfully both inside and outside.

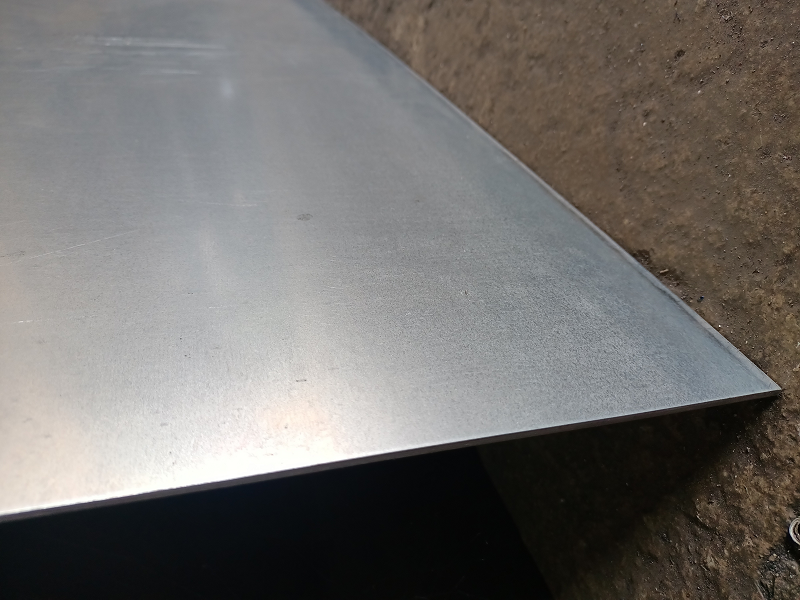

We recommend to carry out cold mechanical processing, so as not to damage the zinc protective layer.

Cutting the galvanized sheet

For cutting, it is recommended to use guillotine, scissors, water jet cutting or any other means that does not lead to sheet overheating. Cutting with the angle grinder or oxyacetylene device shall lead to damages of the zinc layer. It is also recommended to make cold drilling by cutting.

Galvanized sheet jointing

It is recommended that galvanized sheet be joined by screws, rivets, etc. The galvanized sheet can be welded, but because the melting temperature of zinc is lower than that of iron, the zinc layer is affected.

If, however, hot-work on the sheet is necessary, the damaged part may be reworked using zinc-rich paint.

How do you store galvanized sheet?

Uses of galvanized sheet

Constructions: shutter, door, partition wall, false ceiling, parapet;

Home appliances: washing machine, refrigerator, air conditioning, fan, cooking machines;

Auto-mobile: door, wing, hood, ceiling;

Others: electrical panels, cable bedding, metal housings.

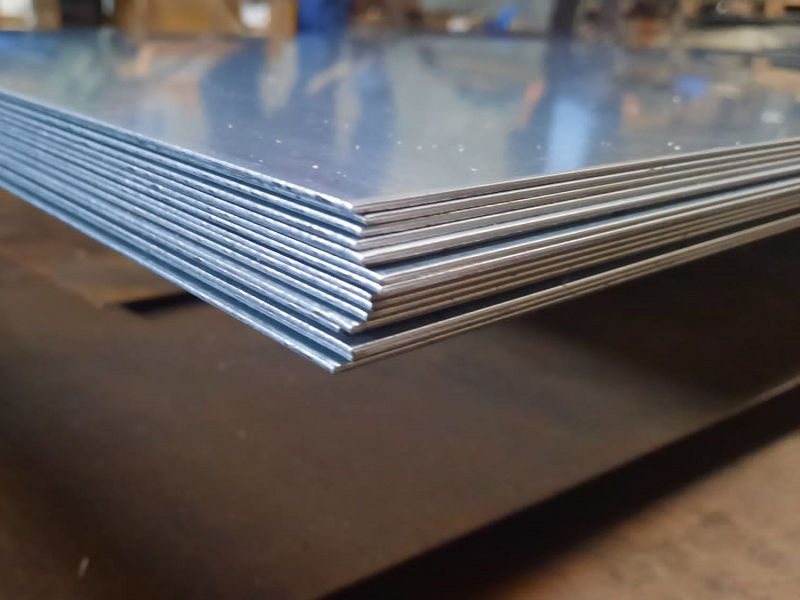

Technical data for hot galvanized sheet:

Production standard for galvanized sheets: according EN 10143 / DIN 59 232

Steel grades according to EN 10142: DX51 D, D DX53, DX54 D Z

inc coating (g / sqm) Z100, Z140, Z180, Z200, Z225

Surface conditon and dimension tolerance: according to EN 10143

Quality certificate: type 2.2 or 3.1B, according to EN 10204